Products & Services

CEC manufactures high end machined spindles used in various application like Grinding, Milling, Boring And Special Purpose Machines.

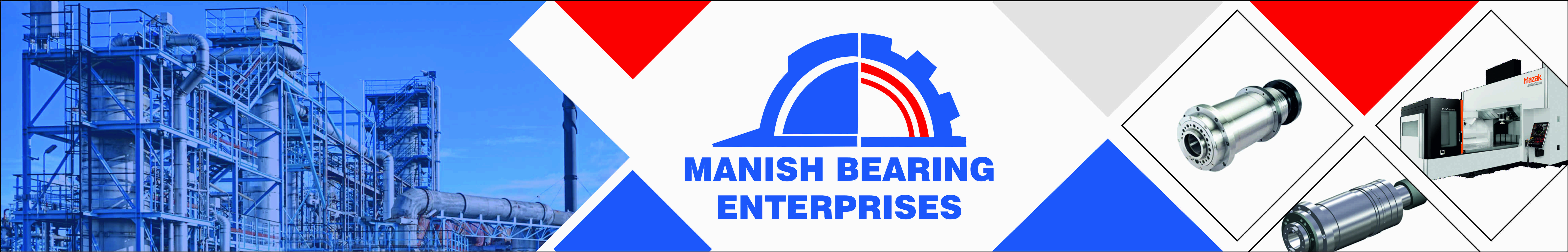

1. High Frequency Spindles

This High Frequency Drilling Spindle offered by us is recommended where positional geometric accuracies are very important. These spindles are used where closely spaced bores or drilled holes are grouped. The High speed drilling Spindles are mostly used in drilling of very small holes in work piece like Printed Circuit boards. Our High Frequency Drilling Spindles are available in both Manual Tool clamping provision and Automatic Tool Clamping (ATC) provision.

Features:

- Guaranteed concentric accuracy within 0.002 mm (2 microns).

- Available in Water as well as air cooled motors.

- Best option for high speed drilling/ Engraving applications.

- Compact design.

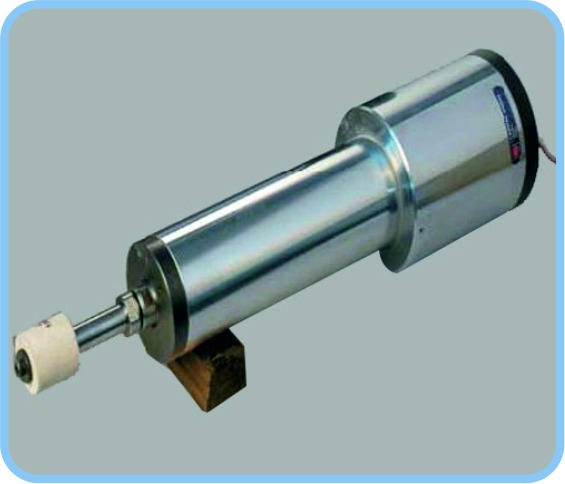

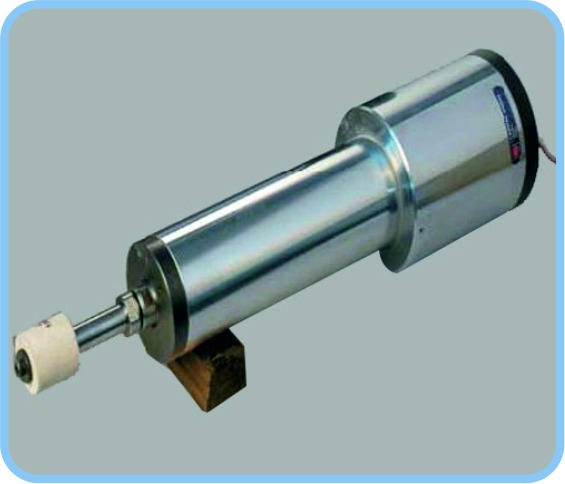

Deep Hole Grinding Spindles

Banking on our enriched industry experience, we are engaged in offering a huge gamut of High Frequency Deep Hole Grinding Spindles. These Grinding Spindles are helpful in conditions where the standard spindle quill/ arbor are unable to reach. Our Spindles are generally tailor made designs and made to job suitability.

Features:

- Guaranteed concentric accuracy within 0.002 mm (2 microns).

- Grind deep bores even up to 2 Meters depth

- These spindles can be mounted on vertical turret lathe.

- Spindles are used as Grinders on boring & VTL machine

- Very easy to handle and maintain.

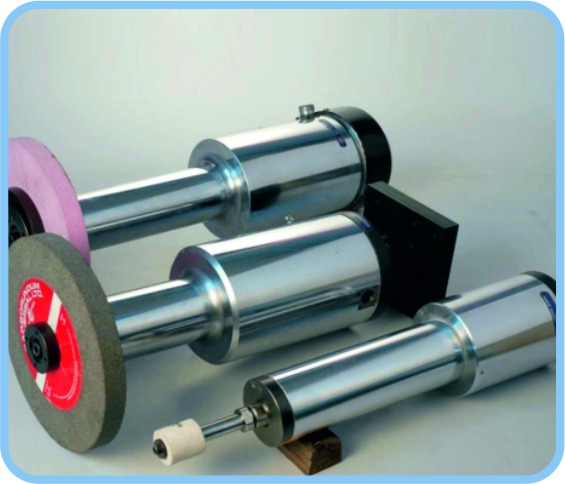

Internal Grinding Spindles

Our company is engaged in offering superior grade High Frequency Internal Grinding Spindles.Our Spindles are designed up to 1, 25,000 RPM. Motor is designed with very low loss of magnetic core lamination.

Features:

- Guaranteed concentric accuracy within 0.002 mm (2 microns)

- Designed up to 1, 25,000 RPM

- 50 KW Power

- Very high axial and radial stiffness values

- High metal removal rates

- Increased part output

- High torque and high power values

2. Belt Driven Spindles

We ‘Capital Engineering Corporation’ are engaged in manufacturing, exporting, supplying and providing services of a wide range of Machine Spindles. These products are designed and developed in CAPITAL ENGINEERING’s state-of-the-art manufacturing unit. Our highly experienced and trained team is capable of manufacturing spindles as per customer specific requirement.

Internal Grinding Spindles

Banking on our enriched industry experience, we are engaged in offering a huge gamut of Belt Driven Internal Grinding Spindles. These spindles are manufactured for Internal Grinding operation for small medium & large dia bores. Our range is suitable for Indian as well as imported machines.

Features:

- They are available in diameter sizes like 60, 80, 100 and 125 etc

- They can be customized according to requirements

- These are grease lubricated for long life

- Oil mist, Oil jet and Oil dipped lubrication spindles can be manufactured

- They are easy to use and maintain

- They provide high performance and low maintenance.

3. Work Head Spindles

Work Head Spindles are having standard models but special spindles are also made as per customers' requirements.

Features:

- Morse taper from MT1 to MT5 or straight bore in the main shaft

- Chuck or work-head plate can be mounted on it

- Spindles can be mounted on Grinding machines

- Pulley having V-grooves is provided at one end of the shaft

- Spindles can be fixed in the body

4. Lathe Spindles

We are engaged in offering a wide range of Lathe Spindles. These spindles are driven by a tangential belt system and used widely in milling applications. They are available in various sizes with a wide variety of speed and power range. The belt-driven milling spindles with their design flexibility, diversity, and performance are suitable for a wide range of milling applications.

Features of Belt Driven Milling Spindles:

- Guaranteed concentrically accuracy within 0.002 mm (2 microns).

- All Spindles are dynamically balanced.

- Variable RPM can be achieved by using stepped pulley or change of pulley.

- They are ideal for moderate to heavy combined radial and thrust loading associated with milling cutters.

- The spindles are arranged for air purging both front and rear.

- They are arranged with milling taper as the tool interface.

- Automatic Tool clamping system can also be provided on request.

- The housing style can be cartridge, flanged cartridge, foot Mount or block style.

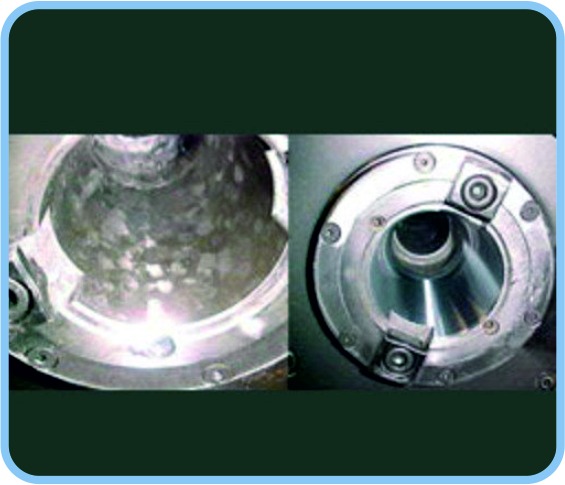

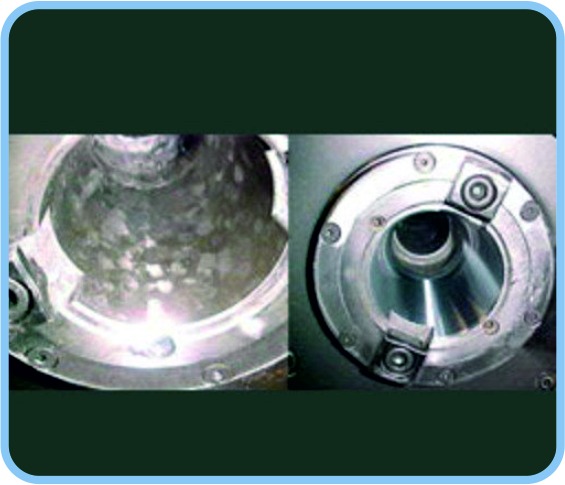

5. Re-Grinding of Spindle Bore

After prolonged use of spindles, or accidents, The Female Cavity of the spindle gets pits and thus gets damage, which results to variation in the end job.CAPITAL Offers Spindle Shaft Re-Grinding Services where we Regrind the spindle shafts and bring it to original Accuraccy.During Grinding Process, the Female cavity is Matched with the gauges and Finally tested with the Mandrel and checked at the distance of 300 mm to confirm the accuracy of spindle Shaft same as new.

6. Hard Chrome Plating On Spindle Shaft

Because of wear and tear, the bearing seats and Geometrical Accuracy of spindle shaft disturbs, which can cause chatter marks on the end job. To rectify such problems, we offers Hard Chrome Plating Services on bearing seats of shaft and thus regrinding the shaft to enable to reuse the older shaft.

7. Rewinding Of Spindle Motors

With Experience of Over 30 years, CAPITAL Engineering can Rewind motor of Any Brand of Spindle and Any Application of Spindle Like same as new. The Range of Motor power which we can rewind starts from 100 Watts to 100 KW.CAPITAL Can also help you to replace Complete Stator and Rotor, in case the Stator or Rotor is non repairable.

8. Precision Bearing Replacement Services

We keep Huge Stock of Steel ball and Ceramic Ball Angular contact bearings of Brands Like NSK, RHP, SKF/ SNFA etc. Most of the repairable spindles require to repair within very limited time. CAPITAL has capability to replace bearings of your Spindle with finest accuracy to rebuild the spindle same as new.

9. Spindle Observation Services

There are cases where it is difficult to bring the spindle at Capital Engineering Facility, we also provide the Spindle Observations Services where our experts can visit your factory and can give you the estimation and work which needs to be done to repair the spindle.